One-Stop Custom Silicone Compression Molding Services

As a custom silicone compression molding services company, we can help you turn your design into reality.

Start Custom Silicone Parts Quote

Specialists in Silicone Rubber Compression Molding Services

As a seasoned manufacturer in the domain of custom silicone compression molding products, our expertise extends over 15 years of crafting quality silicone products, rubber parts, and LSR components using both solid silicone compression molding and liquid silicone rubber (LSR) injection molding techniques.

We specialize in the development of custom molds for silicone compression and silicone injection, catering to a variety of project scales, from small batch productions to high-volume orders. For insights into the optimal solution tailor-made for your silicone molded products, we invite you to reach out to us.

We take pride in delivering top-notch silicone goods, encompassing office supplies, culinary tools, children’s playthings, everyday essentials, protective casings for electronic devices, smart wearable technology, silicone keyboards, gaskets, O-rings, rubber seals, rubber bases, and intricate medical components.

We are particularly proficient in supporting start-up ventures and mid-tier projects with requirements for swift prototyping and minimum order quantities right from the outset. Entrust us with your custom silicone compression molding needs and silicone rubber mold manufacturing projects, confident in our commitment to the shortest possible turnaround times and the most competitive pricing.

What Are the Different Types of Compression Molding?

Hot Compression Molding is a specific process where the composite is initially situated within the open silicone rubber mold / tooling that is heated. The silicone tooling is then shut and pressure exerted to ensure the material thoroughly fills the entire area of the tool. This pressure and heat is sustained throughout the curing duration.

On the other hand, Cold Compression Molding is a manufacturing methodology where the curing transpires under ambient conditions. Within this process, the fortifying material is first positioned onto the mold. Subsequently, the liquid resin adhesive/curing agent is poured, and under a specific pressure and timeframe, the final product takes shape. The molding temperature in compression molding generally does not surpass 160 degrees, and the forming pressure ranges between 0.07 to 0.35 MPa. Hence, this method permits the use of economically priced materials for the mold. However, it is important to make a note that the efficiency of production and dimensional precision of cold compression molding is slightly lesser compared to hot compression molding. This method is typically suited for the manufacturing of large scale, medium-quality products.

Advantages and Disadvantages of Silicone Compression Molding?

Advantages of Silicone Compression Molding

- Cost is controllable and affordable;

- The mold manufacturing cycle is short;

- Short lead times for manufacturing silicone parts;

- Ability to produce complex and fine shapes;

- There are many colors available;

- Wide applications of part size;

Disadvantages of Silicone Rubber Molding

- Limited accuracy;

- Manufacturing process times are slower;

- Slower manufacturing process time

- Manual deburring is required;

- Not suitable for parts with complex assemblies

Why Choose Our Custom Silicone Compression Molding Service

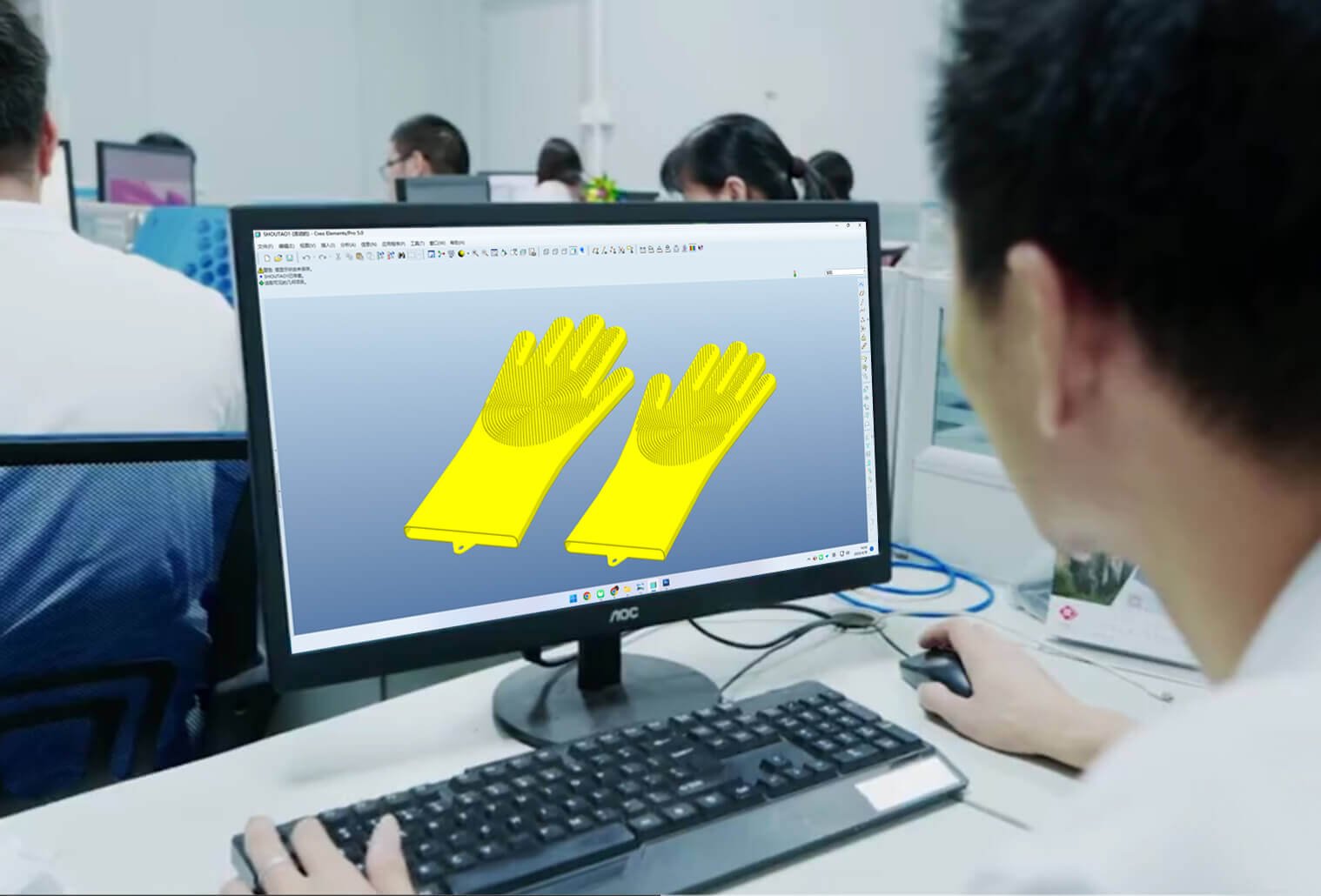

Silicone rubber Parts R&D

Silicone Rapid Prototyping

Silicone Rubber Mold Making

Silicone Compression Molding

Process Of Silicone Compression Molding

We works with leading manufacturers from different industries to support growing demands and streamline their supply chain. The digitalization of our custom CNC machining services helps more and more manufacturers bring their idea to products.

Silicone Products Design & Drawing

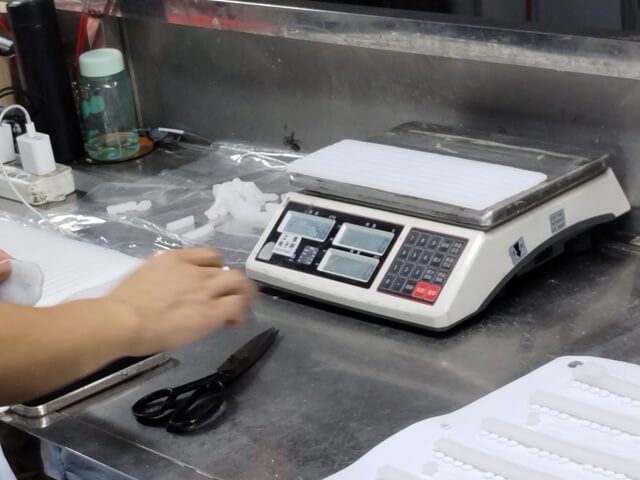

Silicone Rubber RAW Material Mixing

Weighting silicone material before molding

custom rubber parts silicone molding

silicone Rubber products Burr Removal

custom logo on silicone products

Final Finished Silicone Products

- Selection of Silicone Material

- Application of Coloring Agent

- Accurate Weighing and Shaping

- Loading the Silicone Material into the Mold Cavities

- Vulcanization Process

- Extracting the Molded Silicone Parts

- Burr Removal

Every silicone molding project begins with choosing the right silicone materials. This is guided by the specific requirements of the product and application. When introducing new silicone goods to customers, we draw on our expertise to recommend appropriately suited materials.

The raw silicone material resembles a milky white to translucent, viscous substance that lacks resilience and strength. For the silicone material to meet the client’s demands and adopt a certain hue, a medley of ingredients such as vulcanizing agents, reinforcing fillers, accelerants, and colorants are blended in.

The output of this detailed and intricate process is a well-blended silicone mix, which is pivotal in ensuring the success of the silicone compression molding process.

Upon achieving the right blend of the silicone material, our technicians carry out precise weighing and mold it to perfectly coincide with the required dimensions for the part in question.

The silicone blend is then fashioned into large rolls, protective films safeguard it from dirt or dust. It is subsequently sliced into sections by an automated machine. The dimensions of these slices are calculated based on the weight of the silicone part intended for formation. This practice simplifies the molding operator’s task.

The silicone mold filled with the material is subjected to pressure between the top and bottom plates of the compression machine.

The silicone is heated and solidified via the hot plate application, and sustainable heat and pressure application ensure complete curing of the raw material. The silicone product forms once the material solidifies under this high temperature and pressure environment.

Our facility is equipped with fully automatic vacuum vulcanizing machines that yield superior silicone parts by liaising with our skilled operators.

Once the silicone solidifies entirely, the vulcanizing machine automatically eases the pressure, and the mold cavity emerges for the operator to remove the molded silicone parts and prepare for the next vulcanizing cycle.

Silicone burrs or the slim layer of material that appears along the mold’s dividing line is an outcome of the high-pressure and low-viscosity nature of silicone material.

To keep burrs at a minimum during the vulcanizing process, sound design, improved molds, and precise material weights are employed. Burrs are primarily eliminated manually, although low-temperature deburring approaches may be used in some situations.

Custom Silicone Parts Using Compression Molding That We Offer

We customize a wide range of silicone and rubber molded parts from rapid prototyping, silicone compression mold making, small batch production to high volume orders.

Frequently Asked Questions

Silicone Compression Molding offers several advantages, making it an attractive option for many applications. It’s well-suited for both low and high-volume production runs and can efficiently handle a wide range of product sizes and complexities. The process permits the use of high-viscosity, high-strength silicone rubber, allowing the creation of products with exceptional durability and resilience.

Moreover, Silicone Compression Molding enables the production of parts with excellent dimensional stability, which is crucial when tight tolerances are required. It also facilitates the manufacturing of parts with intricate designs or multiple cavities, which might be challenging with other molding techniques.

Applications of Silicone Compression Molding span across industries such as medical, automotive, electronics, aerospace, and consumer goods. The process is often used to create seals, gaskets, keypads, electrical connectors, and many other products.

Medical Devices: Silicone Compression Molding is employed extensively in the medical sector due to silicone’s biocompatibility and durability. The process is used to produce components such as seals and gaskets for medical devices, silicone valves, and even specific parts of implantable devices. As of 2021, the global medical device market was valued at approximately $450 billion, and silicone components play a crucial role in many of these devices.

Automotive Industry: Silicone compression-molded parts such as gaskets, seals, and hoses are integral to the automotive sector. These components help ensure vehicle reliability and safety by withstanding extreme temperatures and resisting various automotive fluids. The global automotive silicone market was estimated to be around $3 billion in 2020, reflecting the significant use of silicone in this industry.

Electronics: Silicone’s excellent electrical insulation properties make it ideal for electronic applications. Silicone compression molding is used to manufacture keypads, connector seals, and insulation pads for electronic devices. With the global consumer electronics market size projected to reach $1.5 trillion by 2027, the demand for silicone components is expected to remain robust.

Aerospace: In the aerospace sector, where components must withstand extreme conditions, silicone compression molding is used to create seals, gaskets, and insulation parts. These components must be highly durable and able to resist temperature fluctuations and exposure to various chemicals. In 2019, the aerospace and defense market was valued at $384 billion, underscoring the considerable role of silicone components in this sector.

Consumer Goods: The process is also used in the manufacture of consumer goods, like silicone kitchen utensils, watch bands, and wearable technology. The global market for silicone in consumer goods was valued at over $7 billion in 2020, reflecting its widespread use in everyday products.

Silicone Compression Molding is a high-volume, high-pressure method used to manufacture high-strength, complex composite parts. It’s commonly utilized in the creation of silicone seals, gaskets, and O-rings.

In this process, uncured silicone rubber is placed directly into the open mold cavity. Then, the mold is closed and put under high pressure to force the silicone to conform to the mold’s shape. The applied pressure ensures that the material makes contact with all mold areas. The mold is then heated, leading to curing or vulcanization of the silicone rubber. Once the part has fully cured, the mold is opened, and the part is extracted.

This method can deliver robust precision parts with excellent repeatability. The main benefits include the ability to mold large and complex parts, better control of wall thickness, and the ability to use various silicone compounds. However, it is relatively slower than some other molding methods, and its precision level might not be suitable for extremely detailed parts.

The cost of customized silicone compression molding generally consists of the following parts.

The first is, silicone product prototype.

The second is, the cost of manufacturing silicone compression molds.

The third is, the cost of a single silicone compression molded part.

Flexible to suit your needs. Please send drawings for your free quote.

- Versatility: Silicone, as a material, is compatible with diverse applications due to its extensive range of characteristics, like durability, flexibility, and resistance to high temperatures. It can be molded into various forms, sizes, and shapes without losing its core properties.

- Cost-Effective: Unlike other molding processes, compression molding doesn’t require a complex setup or expensive machinery, making it a cost-effective choice on many projects, especially for producing large parts or small, less complicated production runs.

- Exceptional Durability: Products made via silicone compression molding typically exhibit excellent resistance to harsh environmental conditions, extreme temperatures, chemical exposure, and aging. This makes them ideal for use in industries like automotive, medical, food and beverage, and electronics.

- Design Freedom: The moldability of silicone allows for great flexibility in design. From simple to complex geometries, a variety of patterns, logos, and textures can be achieved through compression molding.

- High Precision: Silicone compression molding allows for manufacturing parts with high dimensional stability and precision, ensuring that the final product fits its application perfectly.

- Environmentally Friendly: Silicone is a more sustainable option compared to many other materials. Its production process has less environmental impact, and silicone products are recyclable under the right conditions.

- Speed and Efficiency: Silicone compression molding can be a quicker process compared to others like injection molding, making it good for both prototyping and mass production.

- Material Efficiency: With silicone compression molding, there is less material wastage as excess material can often be reused, contributing to the overall cost-effectiveness and environmental friendliness of the process.

- Compression Molding: This is a traditional technique where a pre-heated silicone rubber material is placed into a heated metal mold. The mold is then closed, applying both heat and pressure, to fully cure the rubber while it adopts the shape of the mold. It’s ideal for high-strength, complex geometries and cost-effective for small production runs or large components.

- Transfer Molding: A technique where the silicone rubber is heated and then forced into the mold using a plunger. It allows for more detailed designs and offers shorter cycle times compared to compression molding. It’s used for rubber parts that require tighter dimensional tolerances and more intricate design details.

- Liquid Silicone Rubber (LSR) Molding: A popular type of injection molding that is commonly used for creating parts that need to be strong yet flexible, and resistant to extreme temperatures. Since the process uses liquid silicone rather than solid silicone, the curing time is reduced, and the process is suitable for mass production.

- Injection Molding: Similar to LSR molding, but the process involves injecting solid silicone rubber into a heated mold. This process is used for producing high precision parts in large volumes, but the startup costs can be high due to the need for specific injection molding machinery.

- Overmolding: This is a process where silicone rubber is molded over a base layer – typically made of metal or plastic – to create a multi-material component. This is often used in applications to enhance grip, insulate, or offer protective qualities. It can be achieved using both injection and compression molding techniques.

- Rubber to Metal Bonding: This is a special type of overmolding where the silicone rubber is bonded to a metal substrate. This creates a part with the structural strength of metal and the flexibility and resistance properties of silicone.

CNC machining starts with a computer, on which designers prepare a part using CAD (Computer-aided Design) software. This digital part is then converted into a format that can be recognized by a CNC machine.

Instructions are sent to the CNC machine in the form of “G-Code” after which the machine can start cutting.

Most CNC machines have a “worktable” and work holding device to keep a block of material — known as the “workpiece” — in place. The worktable may or may not move, depending on the style of the machine.

When machining starts, the cutting tool makes contact with the workpiece, cutting away layers of material. The tool and/or workpiece is moved and/or rapidly rotated according to the G-Code instructions so that cuts are made in exactly the right places until the part is finished.