Your Trusted Silicone Mold Manufacturer - One-Stop Custom Silicone Mold Manufacturing

As a leading silicone mold manufacturer, we provide high-quality custom silicone molds for various industries.

- Tight Tolerance of 0.02 mm

- Professional review and communication

- Rapid Prototyping

- Engineering technical support

Custom silicone mold manufacturing for Production Parts

Manufacture your silicone rubber parts quickly and accurately. We offer custom silicone molds to help your project be a success. We work with you to understand the uniqueness of your project and then develop a precise silicone compression and silicone injection mold design based on your specifications. Our professional technicians handle complex issues in the mold production process.

All-in-one Solution for silicone rubber Mold manufacturing

Our versatility allows us to develop prototype tools and production molds at affordable prices. With the fastest possible lead times, our capabilities help us optimize production and bring your products to market faster. Are you ready to take your silicone product and rubber parts production to the highest level? We are always ready to assist you during the production process.

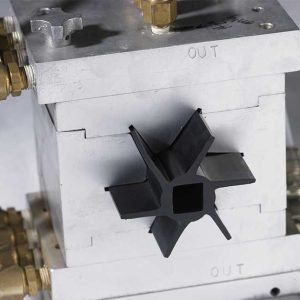

Silicone Compression Mold And Injection Mold and Molding

We produce different types of silicone compression and injection molds, from the most basic silicone compression molds to the most complex liquid silicone injection molds and overmolding molds. Our main goal facing customers is “to provide the shortest delivery time at the best price by providing the best quality molds and services.”

Silicone Prototyping

Silicone Mold Design

Silicone Rubber Mold Manufacturing

Silicone Mold and LSR Injection Molding

Our Silicone Compression and Injection Mold Processes

See how we process your orders, from quotation to tooling, as our machines and efficient team ensure you receive your molds and parts within the scheduled lead time.

Request for Quote

Send us an email with your needs or drawings, etc., and our professional silicone engineers will respond within 24 hours to ensure the process goes smoothly.

DFM Report

To ensure we can produce this silicone mold, we will conduct a feasibility review of your silicone product design to ensure we can meet the requirements before starting production.

Mold Flow Analysis

If it is liquid silicone and the product is relatively complex, mold flow analysis will be done to verify the mold design project.

Mold Tooling Production

Start producing mold tooling using the materials and finishes of your choice based on your specific application needs.

T1 Sample Verification

Before manufacturing silicone parts, we will provide T1 samples for your inspection to ensure accuracy and quality.

Low Volume Production

After completing the trial production phase, we move into low-volume production, using advanced processing technology to manufacture parts quickly and efficiently.

Strict Inspection

Strict inspection processes, including functional, dimensional and visual inspection, ensure parts meet required specifications and are of high quality.

Delivery

After a thorough inspection, we will deliver your product to you as quickly as possible while ensuring its safety.

Surface Finishes of Custom Silicone Molds Manufacturing

As a silicone rubber mold supplier and manufacturer, we offer custom silicone mold manufacturing, silicone rubber mold making, silicone compression mold, and liquid silicone rubber mold making. The surface treatment of the Silicone Rubber mold is usually completed during the silicone mold manufacturing process.

- Smooth

- Semi-Smooth

- Matte

- Textured

Smooth

Semi-Smooth

B grade finishes use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Custom molded plastic parts that undergo B grade finishing have a matte surface texture.

B grade finishes use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Custom molded plastic parts that undergo B grade finishing have a matte surface texture. Matte

Textured

Why choose us to manufacture silicone rubber mold for compression and injection molding

We apply strict quality standards to each silicone mold to ensure consistency and quality of molded parts. Our experts work with you from prototyping to production, optimizing rapid tooling for prototypes and production parts. Every step of our mold production reflects our commitment to quality and customer satisfaction.

High Quality Products

Our silicone molds are of the highest quality and our inspection process is excellent, reducing the occurrence of defects.

Industry Experience

Our company has decades of combined experience to provide you with the best results

Mature Technical Team

Our technical team is experienced and professional to provide you with the best experience.

Competitive Pricing

Our experienced silicone designers, low overhead and developed supply chain save costs for our customers.

Effective Supply Chain

We have experienced silicone industry and supply chain engineers to optimize processes and ensure we are lean and on time.

After-sales Service

After delivery, you can rely on us to continue to meet all your needs quickly and efficiently.

Materials for Silicone Rubber Mold and Compression & Injection Molding

These are commonly molded silicone rubber that our compression/injection molding service provides. After knowing the basics of materials, like common grades, brands, advantages, and disadvantages, choose the right silicone molding material depending on your application requirements.

Tooling Materials

Before silicone compression/injection molding process starts low or high-volume production, a high tolerance CNC machined custom silicone tooling is needed. Most commonly used materials include:

Tool Steel:

P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738

Stainless Steel:

420, NAK80, S136, 316L, 316, 301, 303, 304

Aluminum: 6061, 5052, 7075

More Details>>

Plastic Materials

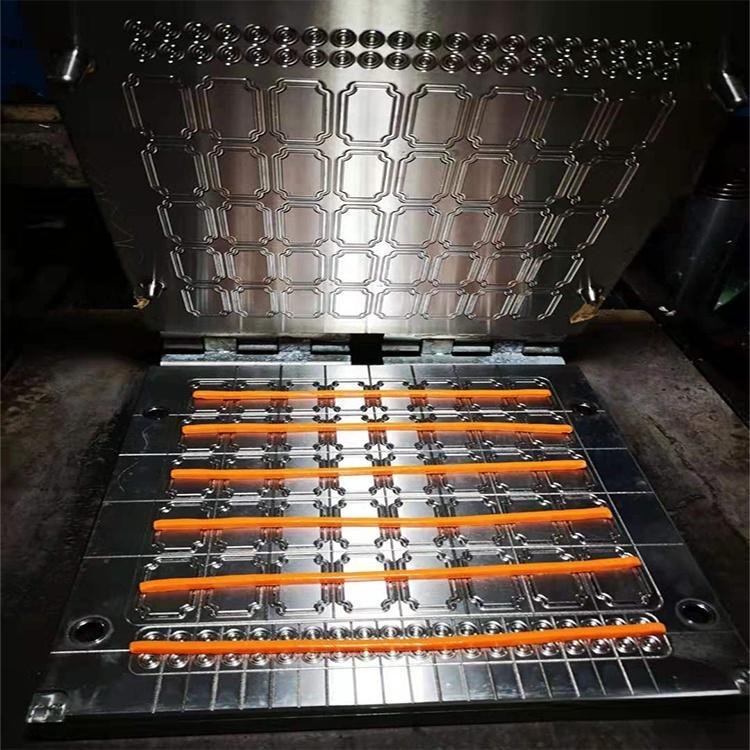

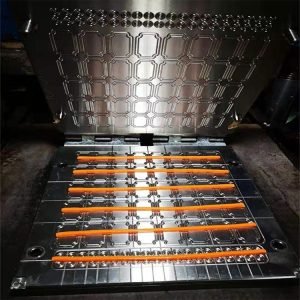

Silicone Rubber Molds and Tools Gallery

We are good at manufacturing silicone rubber molds such as silicone compression molds, liquid silicone molds, silicone overmold, silicone dripping dispensing molds, and silicone rubber extrusion molds.

Compression/Injection Molding from Prototyping to Production

Rapid Silicone Prototype Tooling

Get easy design feedback and validation through superior quality prototype tooling. Create small batches of silicone molded parts with excellent compression/injection molding prototypes. We excel at manufacturing prototype molds within days to ensure you perform functional tests and validate market interest.

Silicone/Rubber Parts Production Tooling

We create high-quality production molds for high-volume silicone/rubber parts production. With high-strength, durable tool steel material, our production tooling is suitable for producing hundreds of thousands of parts. We can vary materials and construction methods according to your unique requirements.

Class of silicone rubber mold manufacturing

At out site, we design and create precise custom silicone molds from high-quality materials. Our processes ensure unmatched consistency and repeatability at fast lead times and affordable pricing. Every silicone injection molding we fabricate meets international standards. From one-off projects to small batches and production tooling, we provide durable and reliable mold tools.

Mold Class | Purpose | Shot Life | Tolerance | Cost | Lead Time |

|---|---|---|---|---|---|

Class 105 | Prototype Testing | Under 500 cycles | ± 0.02mm | $ | 7-10 days |

Class 104 | Low-volume Production | Under 100.000 cycles | ± 0.02mm | $$$ | 10-15 days |

Class 103 | Low-volume Production | Under 500.000 cycles | ± 0.02mm | $$$$ | 10-15 days |

Class 102 | Medium-volume Production | Medium to high production | ± 0.02mm | $$$$$ | 10-15 days |

Class 101 | High-volume Production | Over 1,000,000 cycles | ± 0.02mm | $$$$$$ | 10-18 days |

Our silicone compression and silicone injection molding are suitable for a variety of industrial applications

We work with leading manufacturers across diverse industries to meet growing demand and streamline their supply chains. The digitization of our custom silicone compression/injection molding services helps an increasing number of manufacturers turn their ideas into products.

Automotive

Aerospace

Consumer Goods

Medical Devices

Baby

Frequently Asked Questions

Our mold-making process includes 6 steps:

Step 1: Production arrangement: Determine all of the requirements and arrange the production.

Step 2: DFM report analysis: Provide free but detailed production DFM report for further feasibility analysis.

Step 3: Production the mold: Put the mold into production and provide the Tooling Schedule form for the whole cycle for clients to check the process at any time.

Step 4: Free sample to test: Put the mold into production and provide the Tooling Schedule form for the whole cycle for clients to check the process at any time.

Step 5: Mass production:Client confirms the samples are qualified, then officially proceed with the subsequent production.

Step 6: Mold saving: Production is completed and delivered after quality inspection. Mold will be cleaned and properly stored for the next round of parts production.

Tolerance is very important, and if not correctly specified and controlled, assembling will fail. RapidDirect uses ISO 2068-c standard for injection molding tolerances unless tighter tolerance required.

No minimum order quantity, but the oder pricing will be more competitive if qty is higher.

After you place order, it takes about 35 days for mold designing and making, and more 3-5 days for molded parts production.

Generally, we generate the quote after our platform must have considered several factors, including the size of the component, mold complexity, number of injection cavities, materials, post-processing needs, etc.