In choosing between compression molding and injection molding, it’s crucial to consider these additional factors:

Both compression molding vs injection molding are popular methods of creating high volumes of identical parts, but each method is distinct and has its unique advantages. Deciding between them depends on various factors such as material cost, desired material characteristics, production speed, equipment cost, and the design intricacy of the part.

Compression Molding is a method where the molding compound (usually preheated) is placed directly into the mold cavity and pressure is applied to force the material to conform to the shape of the mold. As the material cures, it hardens and takes on the mold’s shape.

Advantages of Compression Molding:

Lower tooling cost:

Compression molds are usually simpler and cheaper to produce than injection molds.

Good for large, fairly simple parts:

Compression molding is ideal for manufacturing larger flat, moderately curved, or fairly simple parts.

Less waste:

As the material is added directly into the mold cavity, there is less waste associated with sprues, runners, and gates.

Can handle high-strength materials:

It’s particularly well-suited to molding fiber-reinforced plastics and thermoset materials which can withstand high temperatures and pressures.

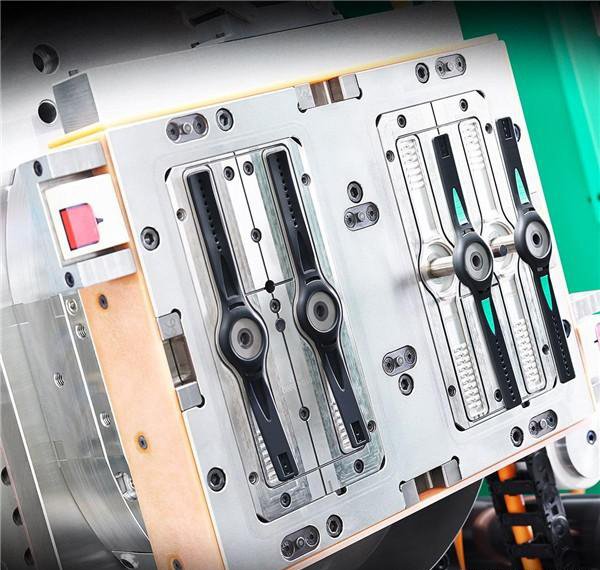

Injection Molding involves heating the polymer until it is liquid and then using pressure to force it into the mold. The material then cools and hardens, taking on the shape of the mold.

Advantages of Injection Molding:

High production speed:

The cycle times for injection molding are much faster than for compression molding.

More design flexibility:

Injection molding allows for more intricate and complex shapes, including parts with many holes or intricate details.

Lower per-part cost for high-volume production:

Though the initial tooling cost can be higher, the unit price per part tends to be lower in high-volume production runs due to its high speed and efficiency.

Possibility for overmolding or insert molding:

You can add additional layers of different materials, which isn’t possible with compression molding.

compression molding vs injection molding, How to Choose? Conclusion

- Part complexity:

If the part has intricate designs, it might be better suited for injection molding. For simpler, larger, bulkier parts, compression molding could be more suitable.

- Materials:

If your customized product requires relatively high strength and hardness, injection molding is more suitable;

If your product is relatively soft, both compression molding and silicone injection molding may be suitable. The specific requirements will depend on the silicone product design and usage requirements.

- Lead Time:

The quicker rate of production makes injection molding favorable if you need products more quickly. The cooling and curing period in compression molding makes the process longer, so bear this in mind if the lead time is a factor for you.

- Labor Costs:

Injection molding machines are typically automated and require less manual labor, which can save on labor costs. Compression molding, on the other hand, involves more manual work for load and unload activities, and can therefore have higher labor costs in some situations.

- Maintenance Costs:

The complexity of injection molds can make maintenance more costly and time-consuming as compared to compression mold maintenance.

- Part Finish:

Injection molding typically produces parts with a better finish, often needing little to no post-production finishing. In contrast, parts made with compression molding might require post-production work to reach the desired finish.

- Material Characteristics:

Certain materials may favor one process over the other. For example, thermosets that cannot be remelted are more often used with compression molding, while thermoplastics that can be remelted and reused are generally more compatible with injection molding.

An experienced compression molding company and injection molding manufacturer can provide invaluable advice based on their past projects and specific knowledge in the field. It’s well worth discussing your project with a potential manufacturer to gain insights into which process will best meet your needs.

Contact our engineers

compression molding vs injection molding

No matter what it is, we can help you solve customized production in one-stop.