Silicone Injection molding and compression molding are both popular methods of molding silicone rubber,

but they have different strengths. Here are some advantages of silicone injection molding compared to compression molding:

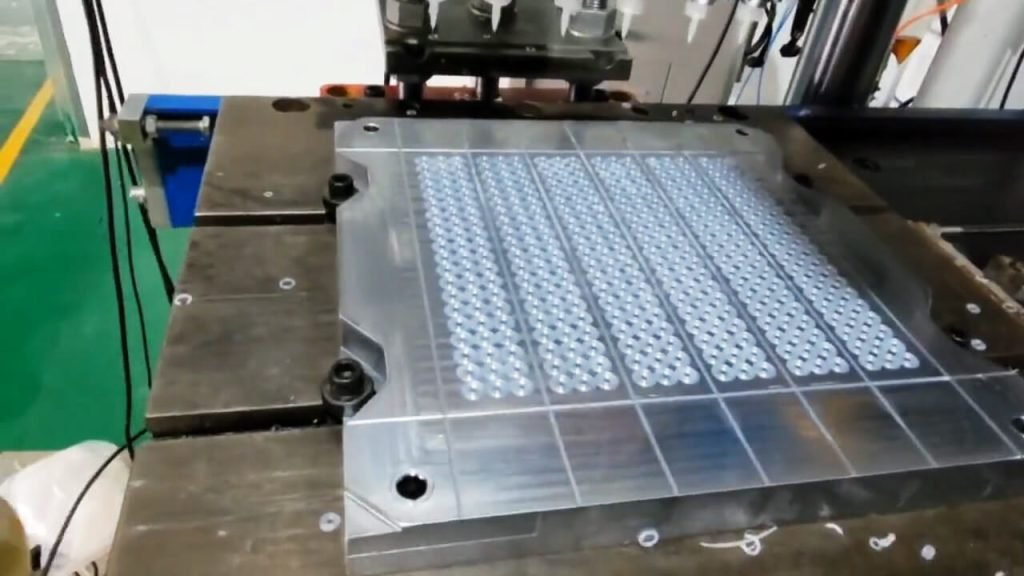

- Greater Detail and Complexity: Injection molding allows the production of intricate and highly detailed parts. The molten material is forcibly injected into the mold, filling in all the nooks and crannies, which can result in a high level of detail and precision, even for complex shapes.

- Faster Production: Generally, the cycle times for injection molding are shorter than for compression molding. This can lead to higher production rates and efficiency, making it a preferred choice for large volume runs.

- Consistency: The automated nature of injection molding allows for extremely high consistency of produced parts. This means that once the initial setup has been created, the process can produce large quantities of identical parts with accuracy and precision.

- Broad Range of Materials: Injection molding can accommodate a diverse set of materials including various plastics, metals, and glasses, offering more versatility for manufacturing industries.

- Less Waste: With injection molding, you usually use exactly what you need as the material is injected directly into the mold. Any leftover material can also be recycled and reused, leading to minimal waste in production.

- Ability to Use Fillers: In injection molding, fillers can be added to the material being molded, reducing density and increasing strength when the part is molded.

Remember, while silicone injection molding has these advantages, it also comes with its own drawbacks such as higher initial setup costs. The decision between injection and silicone compression molding will come down to the specifics of your project and the requirements of the parts you’re producing.