Liquid silicone rubber (lsr, Liquid Silicone Rubber), liquid silicone molding (LSM, Liquid Silicone Molding)

Introduction to LSR/LSM liquid silicone injection molding process.

LSR/LSM liquid silicone molding technology can be used in consumer electronics products such as earphone earmuffs, smart watch straps, medical supplies, electronic cigarettes, automotive connectors, etc.

Silicone, also known as silicone, is a type of polysiloxane (Polysiloxane) whose molecular chain is composed of silicon atoms and oxygen atoms with high bond energy and is not easy to break.

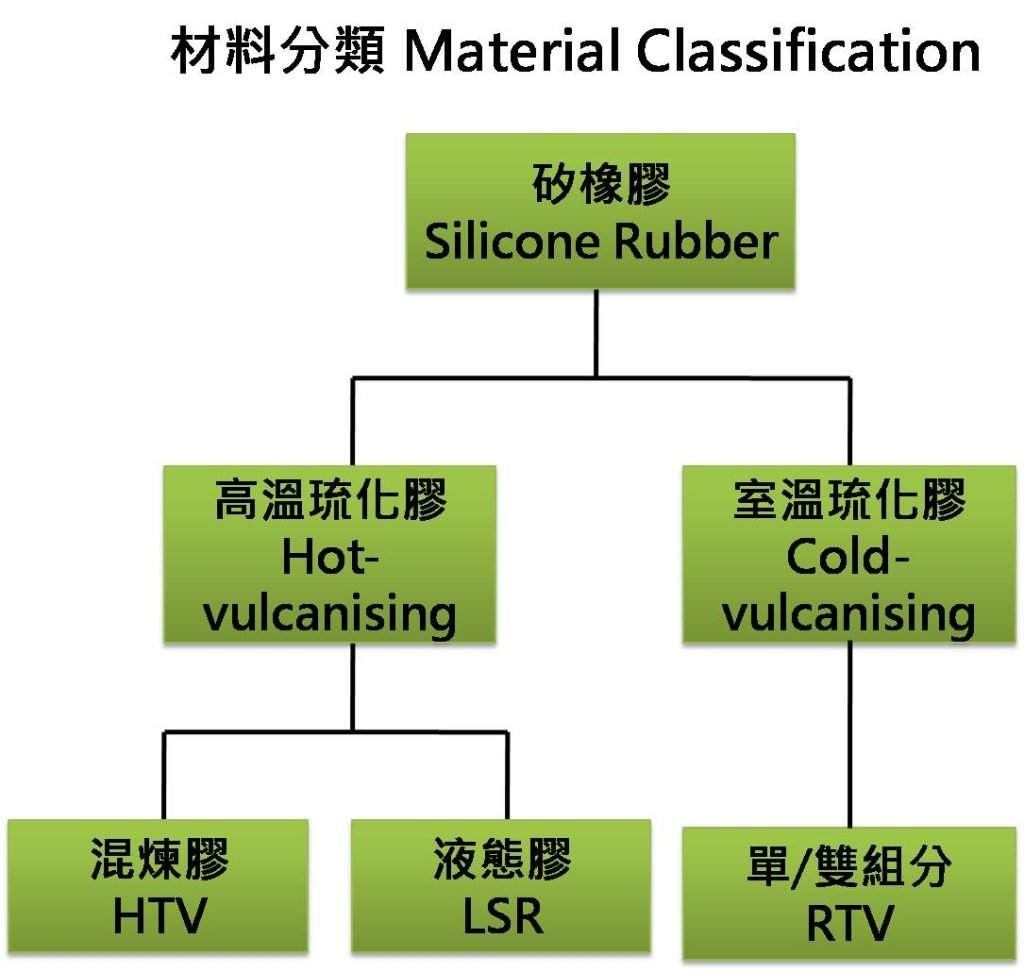

There are many types of silicone, with unique functions and wide range of uses. They are important chemical materials that are indispensable to the national economy and life. They are known as “industrial monosodium glutamate” and “technological development catalyst”. The figure below shows the classification of silicone rubber materials.

JX Silicone Injection Molding Company LSR/LSM liquid silicone molding provides different mold types to meet different needs, such as burr-free molding molds and precision cold runner molds.

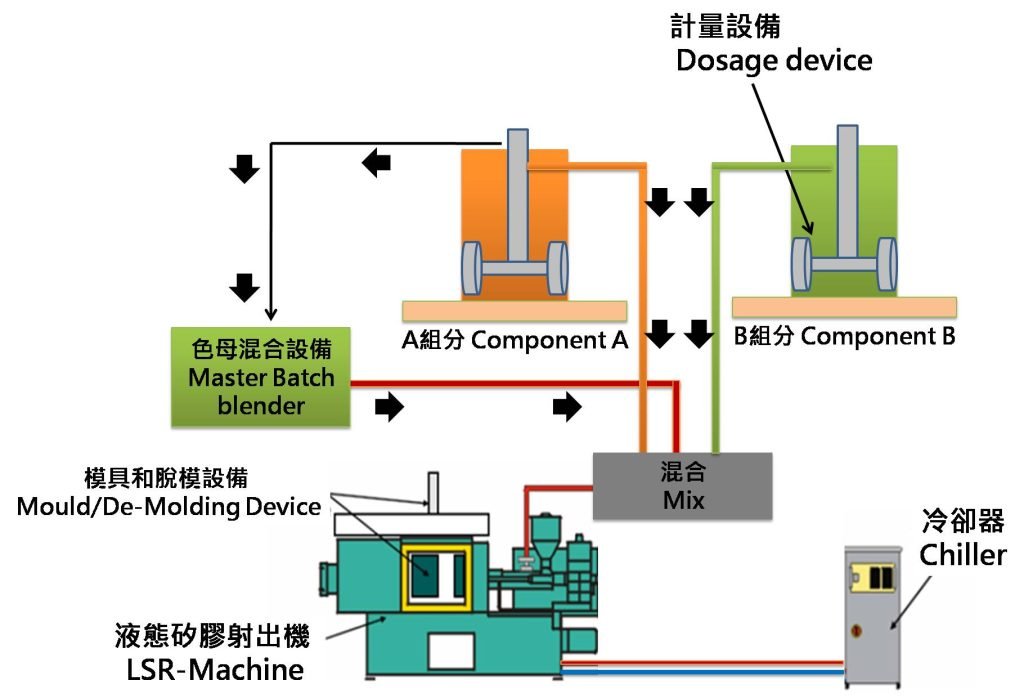

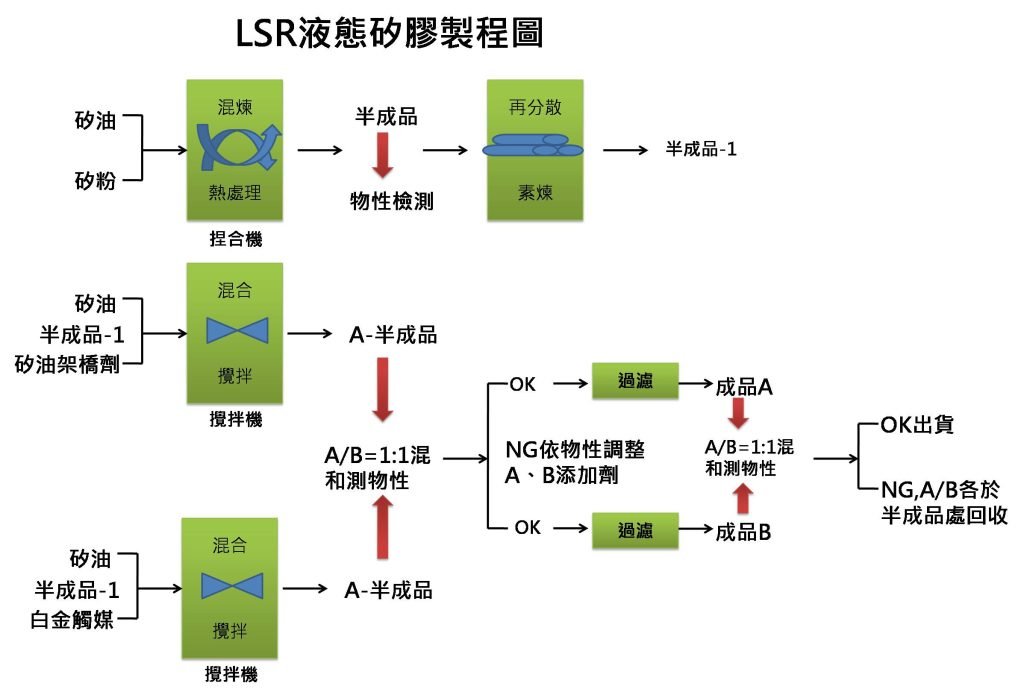

The injection method of liquid silicone molding is to use two liquids A and B to mix and then perform injection molding, as shown in the figure below.

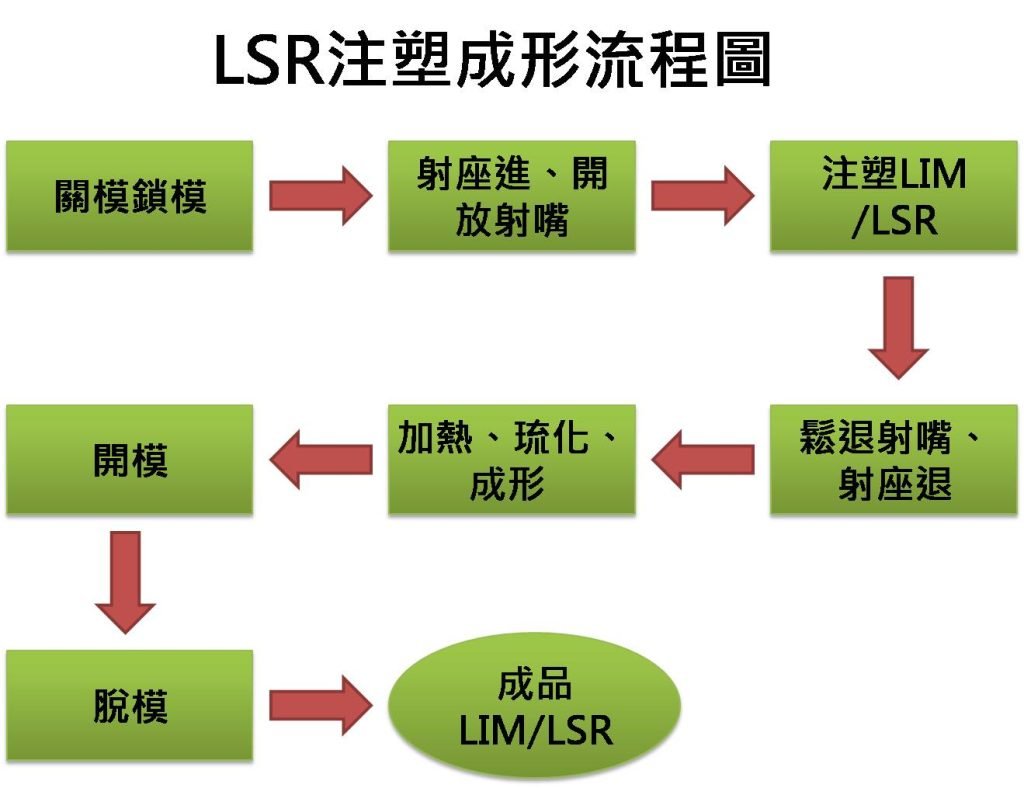

LSR is liquid silicone for injection molding. Although it is high-temperature hardening silicone, it has a lower viscosity than compound rubber and other elastomers. Because it is in liquid form, it can be continuously supplied to the injection molding machine automatically, thus making the product automatic. Molding, it can not only improve production efficiency, but also has excellent physical properties, as shown in the figure below.

Silicone Product Features

Heat resistance: It is still a good material under long-term high temperature (200°C) conditions.

Cold resistance: Still maintaining good toughness at low temperatures (-70°C).

Deformation resistance: It has good deformation resistance.

Chemical resistance: Good oil resistance, chemical resistance, alcohol, and alkaline resistance cannot be invaded.

Insulator: Resistant to water and an excellent electrical insulator.

LSR Silicone Injection Molding Applications

LSR/LSM liquid silicone molding technology can be used in consumer electronic products such as earphone earmuffs, smart watch straps, medical supplies, etc.

Dongguan JX silicone injection molding factory is committed to the research and development of new processes for liquid silicone (lsr) products and the customized production of new products. Our company can provide precision flash-free liquid silicone mold design and manufacturing, liquid silicone rubber (LSR) injection molding, two-color liquid silicone rubber injection molding, multi-material (plastic, hardware, etc.) liquid silicone encapsulation secondary injection molding and other services.

JX company’s products include: liquid silicone products for e-cigarettes, mobile phones, and 3C waterproof accessories, liquid silicone products for automotive electronic accessories, liquid silicone products for mothers and infants, medical liquid silicone products, liquid silicone kitchenware products, industrial sealing silicone products, etc. In particular, we have complete solutions and accumulated rich production experience in liquid silicone-coated parts (silicone-coated plastic, silicone-coated hardware, silicone-coated glass or ceramics, silicone two-color packaged beer).