Custom Silicone OverMolding Service

Quickly turn your ideas and designs into reality with our silicone overmolding services.

Start Your Silicone OverMolding Part Quote

Custom Silicone OverMolding Service

When looking for Silicone OverMolding services, if you want to manufacture satisfactory Silicone parts, you cannot miss our silicone overmolding company.

Silicone Over-Molding is a process where a silicone material is molded over another part, often made of different materials. This process is used to create a single composite piece that combines the advantages of multiple materials.

In general, a substrate, which could be essentially any material such as metal, plastic, or even another piece of silicone, is placed into the mold cavity. Then, liquid silicone rubber is injected into and around the substrate, encapsulating the part in a layer of silicone.

Our custom Silicone Over Molding is a high-precision manufacturing process utilized to fabricate intricate, durable silicone components.

Silicone Over-Molding is commonly used in various industries such as medical, automotive, electronics, and more. It’s favored because silicone is highly durable, flexible, resistant to harsh temperatures and has excellent electrical insulation properties. Plus, it adds a soft-touch and non-slip grip which improves product aesthetics and usability.

This process often requires specialized equipment and technical know-how for successful execution which ensures a proper bonding between the substrate and the silicone without any disfiguration or dislodgement in the product’s intended use.

Silicone Overmolding includes:

Silicone rubber compression over-molding;

liquid silicone rubber (LSR) over-molding;

What Is Silicone Compression OverMolding?

Silicone Compression OverMolding is a specific molding manufacturing process that utilizes heat and force to shape the silicone around the chosen substrate. The term ‘compression’ refers to the method by which the silicone is molded.

In this silicone manufacturing process, a pre-heated silicone material is placed in an open, heated silicone mold cavity. The mold is then closed, and pressure is applied, causing the silicone to fill the mold and envelop the substrate. The silicone compound is then heated and cured (hardened), with the embedded part (made of metal, plastic, or other material), in a process called vulcanization.

Once the curing process is complete, the molded part is removed from the mold. The result is a durable, integrated piece with the beneficial characteristics of the silicone (such as flexibility, thermal stability, and resistance to weather and chemical factors) combined with the functionality of the underlying substrate.

The Silicone Compression Over-Molding process is frequently used in the development of medical devices, electronic components, seals, and gaskets, among other applications. It’s an ideal process when working with intricate designs or when using materials that can’t be exposed to the high temperatures used in injection molding.

Recommend Reading: Silicone Compression Molding

What Is Liquid Silicone Rubber LSR OverMolding

Liquid Silicone Rubber (LSR) OverMolding is a process where a component, often made of a different material (like plastic or metal), is inserted into a mold, and liquid silicone rubber is then injected into the mold, encapsulating the part with silicone.

In contrast to the compression molding process, here, as the name suggests, the silicone rubber is in a liquid form when it’s applied. This allows the silicone to fill the mold more thoroughly and precisely, and it’s typically used for parts with complex geometries or high precision requirements.

After the silicone is injected into the mold, it is heated until it cures (hardens), forming a solid piece that is both flexible and resilient, with excellent thermal and chemical resistance. The final product will have the advantages of both materials, such as the strength of the metal or plastic and the flexibility/resilience of the silicone rubber.

LSR Over-Molding is a highly versatile process used in numerous sectors including automotive, medical, electronics and more. It allows for efficient, high-volume production of parts and components with minimal post-processing, whilst meeting stringent quality and durability standards.

Recommend Reading: LSR Injection Molding

Examining Silicone Overmolding Services

Identify the Silicone Molding Service that Precisely Adheres to Your Distinctive Requirements. Discover, Choose, and Allow Us to Materialize Your Concept into Reality!

Material | Molding process | Mold Cavities | Mold Life | Colors | |

|---|---|---|---|---|---|

Silicone Rubber Compression Molding | Solid Silicone Rubber | Compression | Single or Multi Cavity | About 50,000 times | Single color |

Liquid Silicone Rubber (LSR) Injection Molding | Liquid Silicone Rubber | Injection | Single or Multi Cavity | More than 200,000 times | Single color |

Multi color Silicone Molding, Dispensing(co-injection) Molding | LSR and SSR | Dispensing and compound | Single or Multi Cavity | More than 200,000 times | Multi-color |

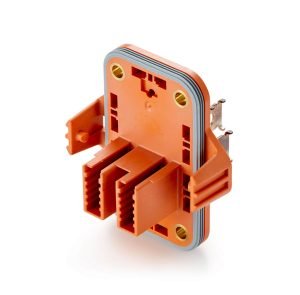

Silicone OverMolding | Silicone Rubber, Plastic, Metal | Over-molded | Single or Multi Cavity | More than 200,000 times | Multi-color or Single Color |

Silicone Extrusion Molding | Solid Silicone Rubber | Extrusion | Single Cavity | About 50,000 times | Single color |

The Advantages of Silicone Overmolding

Silicone Overmolding presents an array of advantages, with one of the most significant being its compatibility with non-plastic substrates. Apart from thermoplastic components and liquid silicone rubber (LSR), this process uniquely welcomes the use of such materials in injection molding, providing a broad spectrum for product manufacturing.

The technique of overmolding lends itself to customization, including the ability to produce products of diverse material composition and coloration. It also offers cost and labor efficiency, especially when compared to manufacturing processes that necessitate the transfer of a part to another mold or machine.

Key advantages include:

• Broad Material Compatibility: Overmolding is harmonious with various types of plastic, such as medical-grade cryogenic PC, PA, PPS, and other materials resistant to high temperatures.

• Time Efficiency: The process boasts a quick curing time, enhancing productivity.

• Clean Finish: Injection molded components produced via this method are free from burrs, resulting in a cleaner and more polished appearance.

• Dimensional Precision: Silicone overmolding allows stringent size control, enabling the production of LSR parts with strict tolerances.

• Superior Quality Control: The process lends itself to enhanced management of quality, resulting in consistent and reliable outputs.

What are the steps in the silicone overmolding process?

1. Design and Check 3D Drawing

Customers provide drawings or designs of silicone overmolding. A professional engineer will inspect the project and help you analyze whether the project requires LSR injection overmolding.

2. Mixing and toning of solid silicone material

After the mold and metal/plastic substrate are prepared. First the metal/plastic part is placed on the silicone mold, then the solid silicone material is placed on the metal/plastic part: the overmolding material is placed on the base element; then the mold is closed and ready for molding.

3. Silicone OverMolding

Overmolded after compression. The metal is completely overmolded with silicone and cured. The silicone mold will come out and open for the molding operator to take out the molded silicone product. Put the raw materials back in for the next round of vulcanization.

4. Logo and surface treatment

Products that are overmolded after silicone compression can be printed by screen printing, heat transfer printing, water transfer printing, laser engraving, etc.

5. Quality Control

All silicone molded products undergo comprehensive quality control before packaging. We will do some burr trimming during quality control.

Applications of Silicone Overmolding

Silicone over-molding finds extensive applications in a plethora of industries due to the distinct advantages it offers like robustness and adaptability. Here are the noteworthy industries and products where the use of silicone over-molding is entrenched:

- Consumer Products

- Automotive Sector

- Medical Sector

- Electrical Industry

- Beauty Industry

Silicone Over-Molding FAQ

- Home&housewares & Appliances ( Kitchen & dining&table & Drinkware &household.etc.)

- Baby & Toys ( Baby care & Baby Feeding & Baby Toy & kids learning toy etc)

- Health & Beauty & Personal Care (Oral care & Beauty tools/Accessories & hair care, etc.)

- Stationery & Office Products(Arts & Crafts& School products & Office products etc. )

- Sports & Outdoor & Garden ( Sports and fitness & Travelling & Outdoor portable etc. )

- Pets Supplies

- Electronic & Cell Phones Accessories ( Protective cover& Case, holder, etc.)

- Automotive & Aerospace & Military

- Smoking products

- Promotional products (Licensed products & Mascot & Gifts & Blind box products)

- Medical products

- Design Flexibility: The process allows for diverse designs and shapes, even intricate or complex geometries. It can also produce parts with varying wall thickness and can accommodate a great range of sizes.

- Durability: LSR parts are extremely durable and resilient. They can resist extreme temperatures, UV light, and exposure to many chemicals, making them suitable for harsh environments.

- Precision: LSR Over-Molding is a highly precise process. The liquid nature of LSR allows it to flow into and fill complex molds effectively, ensuring exact reproduction of the mold’s details.

- Sensory Characteristics: LSR products are soft and flexible, providing a comfortable and pleasing touch. Such haptics often elevate the user experience.

- Biocompatibility: LSR is often used in the medical industry due to its biocompatible nature. It doesn’t react with human tissue or bodily fluids, making it ideal for medical devices and implants.

- Efficiency: The LSR Over-Molding process is automated and capable of high-volume production, which translates to efficient production times and cost-effectiveness when producing large quantities.

- Low Waste: There’s minimal flash (excess material spilling out of the mold) in LSR Over-Molding, leading to less waste and lower materials costs.

The silicone overmolding process is a manufacturing technique used to combine silicone with another material, typically plastic or metal, to create a component with both the durability of the base material and the flexibility or softness of silicone. This process is often used in applications where the product needs to have both structural strength and a soft, tactile surface, such as in medical devices, automotive parts, and consumer electronics.

Here are the main steps involved in the silicone overmolding process:

1. Design and Material Selection

- Design the Part: The first step is designing the part and selecting the appropriate materials. The base material (e.g., plastic or metal) must be compatible with silicone for proper bonding.

- Material Selection: Choose the correct type of silicone rubber (e.g., liquid silicone rubber or LSR) based on the product’s functional and environmental requirements (e.g., temperature resistance, flexibility, biocompatibility).

2. Preparation of the Mold

- Mold Creation: A mold is designed and created, typically using metal such as aluminum or steel. The mold will have two sections: one for the base material (insert) and one for the silicone overmolding.

- Insert Preparation: The base material (e.g., plastic or metal insert) is placed into the mold. Inserts can be pre-formed or molded separately before the overmolding process.

3. Insert Placement

- Insert Loading: The prepared insert (the base part) is placed into the mold cavity. This insert will be the core around which the silicone rubber will be overmolded.

- Positioning: The insert must be carefully positioned to ensure that the silicone rubber adheres to the surface properly and that the part functions as intended.

4. Injection of Silicone Rubber

- Silicone Injection: Liquid silicone rubber (LSR) is injected into the mold cavity around the insert. The LSR is typically injected in liquid form, and it hardens once it is cured.

- Molding and Curing: The silicone is injected into the mold, and the mold is heated to cure the silicone. This curing process is often achieved through heat or ultraviolet (UV) light, depending on the type of silicone used.

5. Cooling and Ejection

- Cooling: After the silicone is injected and molded, the part is cooled to solidify the silicone rubber around the insert. The cooling process allows the part to harden and become stable.

- Ejection: Once cooled, the overmolded part is ejected from the mold. Any excess material, such as flash (extra silicone around the edges), is trimmed off during this step.

6. Post-Processing (Trimming and Finishing)

- Trimming: Excess silicone (flash) around the part is trimmed to ensure the part’s final dimensions are accurate and clean.

- Finishing: Additional post-processing steps, such as surface treatment, printing, or coating, may be applied to the overmolded part if necessary.

7. Quality Control and Inspection

- Inspection: The finished overmolded part undergoes rigorous quality control to ensure it meets the specified tolerances and performance standards. This includes checking for proper bonding between the silicone and the insert, as well as testing for functionality, durability, and appearance.

- Testing: Depending on the application, parts may be tested for specific properties such as flexibility, temperature resistance, or electrical insulation.

8. Packaging and Delivery

- Once the parts pass quality control, they are packaged for delivery to the client or for further assembly into the final product.

No. You can order a one-off prototype or 1,000+ units.

LSR injection molding is a cost-effective and versatile process used by manufacturers in a large number of industries and applications. From LSR overmolded handles to complex electronic assemblies ( case ) , there are multiple reasons why rubber overmolding is a good choice for your project:

Cost and time savings——By molding silicone directly onto a metal or plastic substrate, you’ll save the expense and time required to assemble a complex part manually. This can dramatically reduce your manufacturing costs and turnaround time, allowing you to get your product to market more economically.

Design flexibility——LSR/thermoplastic injection molding is excellent for meeting the complex design requirements of the automotive and medical industries. Silicone rubber overmolding produces parts that are waterproof, airtight, and more resistant to shock and vibrations.

Quality control——The LSR/plastic injection overmolding process offers high tolerance and strict quality control, making it suitable for use in any application where precision is required. We can produce overmolded silicone rubber parts to your exact specifications, including devices that require manufacturing in a Class VII or Class VIII clean room.

There are five key points of FMEA that we should review in depth during the estimation phase:

How do the substrate material structure and physical properties change when the mold is closed?

How do the base material structure and physical properties change during injection and curing? The optimal pressure and temperature should be estimated and selected in advance.

How does the matrix position change during injection? Included in the mold design review meeting checklist.

How does LSR flow during injection? The results from the injection flow analysis software help inform our judgment at the mold design review meeting.